PACKAGING

Food

We offer multiple types of containers and packaging for the food industry, and they all have something in common: they must guarantee to maintain the product’s original quality, as well as its nutritional values, flavor and look.

These films feature low production costs and ease in machine processing. They offer excellent mechanical, optical and barrier properties (depending on their formulation), which can be changed depending on the needs, and they can contribute to extending the product’s useful life.

PACKAGING SOLUTIONS

DISPENSING LAMINATE

Film for automatic packaging, based on a wide range of formulations according to its purpose. From low gauge PE films for frozen foods, to films with high oxygen barrier to increase the product’s shelf-life.

LAMINATING FILM

The Armando Alvarez Group specializes in a range of polyethylene films for laminating. Their main features are their welding capability and optical and mechanical properties, adapting to the client’s needs and/or applications.

As one of the European leaders in this market, measured both by volume manufactured and by the quality of the products and developments, the Group currently exports to numerous European markets, and even beyond the European continent.

The Armando Alvarez Group has several latest-generation extrusion lines, equipped with all the automatic control elements to guarantee a standard of quality that will meet the high demands of this market.

FEATURES

APPLICATIONS

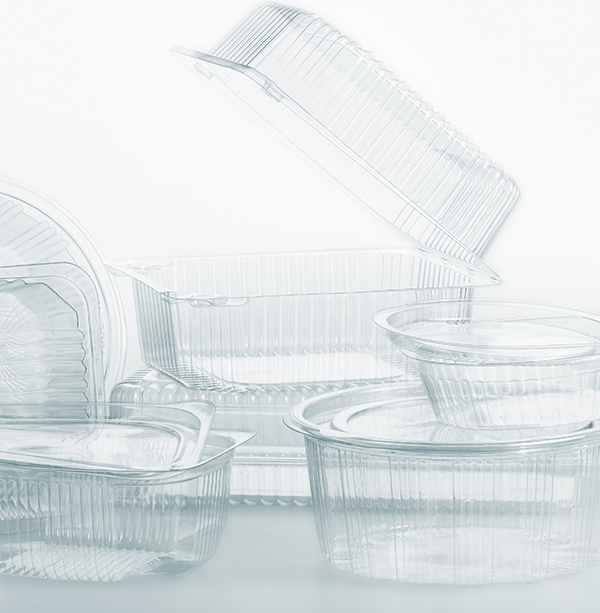

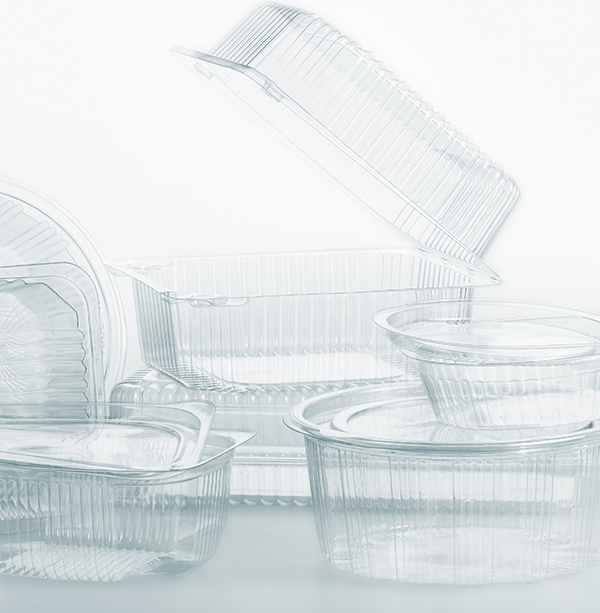

THERMOLAMINATION

This film is normally used in lamination with other usually rigid materials (APET, PS, OPP, ETC) to shape the containers. They are often used as food packaging, as they are structures that provide low permeability to oxygen, contributing to increasing food shelf-life in these containers.

Bag in box

We offer a wide range of co-extruded multi-layer films based on combinations of polyethylene, EVOH and polyamide. These combinations provide excellent optical and mechanical properties, as well as outstanding weldability that allows for packing liquids with full guarantee.

CEREAL

We have developed specific technical structures for the cereal film that protect the packaged product from both moisture and oxygen, if necessary. This considerably increases their shelf-life and preserves their properties for longer.

Our films also make it easier to open the bags thanks to a specially-designed formulation.

LAMINATED FILM WITH ADHESIVES

We manufacture a wide variety of laminated structures that perfectly match the needs and uses of our clients. They guarantee perfect product conservation, ensuring the highest production rates and machinability, with multiple visual options and finishes to ensure the best product positioning.

THERMOFORMED FILM

The Armando Alvarez Group manufactures efficient and sustainable packaging solutions and services for food products, as well as for medical devices and pharmaceuticals. We are in constant contact with our clients, in order to generate added value through our innovations and services.

We produce flexible multi-layer laminates manufactured in an array of co-extrusion technologies using water quenched technology, with varied barrier structures (PA/PE, PA/EVOH/PE, PA/PP, PA/EVOH/PP) as well as single-material products, available for different types of machinery.

We market three products under our CLARITY brand, providing solutions for the food and pharmaceutical industries.